|

Shantou Shanhe Industrial Co., Ltd

|

laminator/ laminating machine/packaging machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

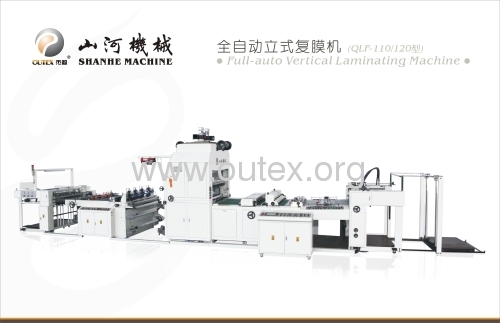

The Full-Automatic High-Speed Vertical Laminating Machine aims at the lamination of the surface of presswork, e.g. books, posters,carton,etc.

Machine's main configuration: Automatic Paper Feeding Machine + Paper Powder Remover +Main Engine Base + Slitting Machine+ Automatic Paper Collecting Machine

III. Technical Specifications:

I. Main Functions & Features

With automatic paper feeding & slitting functions, energy-saving oil temperature roller, magnetic powder tension control, exclusive pneumatic film spreading and automatic constant-temperature hot air blowing control, this high-efficient, safe and energy-saving equipment has good reputation among our users.

1. Paper Feeding Machine: an accurate feeder makes automatic adjustment depending on different sizes of paper through high-speed operation of Programmable Logic Controller by using a highly accurate linear guide and a ball screw in combination with a direct current motor. It is very easy to accurately adjust the position of the air nozzle in relation to paper stack during operation. The distinct stone reel ensures continuous production without stoppage.

2. Automatic alignment system: we use servomotor to replace the traditional continuous variable-speed equipments so that the alignment position among papers can be very accurate. It also implements human-machine intelligent control with automatic manipulation on the touch screen.

3. By using a hot oil circulation system and a mold temperature controller, the large-diameter preheating roll and laminating roll of the main frame are fast in heating, and are reliable and accurate in temperature control so that temperature is evenly distributed. The design of the large-diameter electrically heated laminating roll and glue roller ensures the laminating time and laminating surface, so that the laminating performance and the luminance of the products are guaranteed; it enhances the effect of the product's surface. The large-diameter preheat roll ensures the smooth running of OPP film without displacement.

4. The drying system uses hot air drying with an oil temperature roller to evaporate the glue film, so that a large amount of electric energy is saved by the thermal recycling function. The automatic constant-temperature control system is easy to operate and fast in heating. The design allows OPP film to be dried quickly and steadily with perfect drying effect. Without the result of any deflection or shrinkage of film, the drying system reacts quickly with high heat and wide distribution, and it suits for water-based glue.

5. The automatic hydraulic system allows entry of pressure figure on the human-computer interface. The problem of high consumption of gluing roller and time is effectively eliminated through the automatic control of Programmable Logic Controller, pressure boosting and drop, no-sheet detector and pressure relief, and therefore the production efficiency is greatly improved

6. Paper powder is removed effectively by vacuum absorption in two steps including powder sweeping and static hot-pressing to ensure smooth paper delivery without deflection. The centralized collection and treatment of printing powder is environmental and convenient.

7. With a step-less speed regulator and automatic tension control, the head of our paper coating machine effectively keeps constant amount of coating. The precision coating and measuring hard-chromium plated roller ensures even coating to achieve an accurate coating effect. Meanwhile this machine comes standard with two groups of oil-well pump and stainless oil groove, which are suitable for oil/water based glue. The film pressing and coating device with a direct current motor is reliable, fast and easy to operate. The film roller uses the magnetic powder braking to maintain stable tension. And the exclusive pneumatic film tensioner ensures the tightness of film in film pressing and releasing and it effectively prevents film rolling from breaking down.

8. Automatic slitting function: An air clutch is used instead of traditional friction plates, so it is reliable and convenient and the friction force can be easily controlled by adjusting air pressure. The slitting length may be set as required according to the paper size. The integral operating system automatically accelerates and decelerates depending on the speed of the mainframe. In this way operation becomes easy, labor costs are saved and labor intensity of operators is reduced. The disc type spinning-blade paper cutter of the cutting machine is provided with a six pairs of blades' rotating cutting head, which allow slight adjustment and is easy to operate. In adjustment, its speed can be freely controlled according to paper size by interacting with the pressure roller.

9. The advanced paper collecting structure designs a damper wheel and an upper and lower air blowing structure to effectively eliminates the difficulty and high consumption of flimsy and Level-C paper in collection and improves the smoothness and trimness of paper in processing.

10. The advanced printed circuit boards are under the control of an imported PLC. The Voltage Frequency Converter of the motor is reliable, energy efficient and safe. II. Pictures

III. Technical Specifications:

Model | QLF-110 | QLF-120 |

Overall dimension (LxWxH)(mm) | 13100x2200x3150 | 13100x2330x3150 |

Total weight(Kg) | 11000 | 13000 |

Maximum paper size(mm) | 1080x 860 | 1180x 860 |

Minimum paper size(mm) | 350x 400 | 350x 400 |

Paper thickness(g/m2) | 80-450 | 80-450 |

Laminating speed(m/min) (Depending on theconditions of paper, glue and film) | 7-50 | 7-50 |

Maximum operating pressure(Mpa) | 15-20 | 15-20 |

Laminating temperature | 50-140℃ | 50-140℃ |

Drying temperature | 60-90℃ | 60-90℃ |

Power consumption of moldtemperature controller(kw) | 39(15+24) | 39(15+24) |

Total power(kw) | 75 | 75 |

Practical power(kw) | 45 | 45 |

IV. Brands & Places of Origin of the Main Spare Parts

Brand | Place of origin |

Vacuum Pump (Orion) | Japan |

Programmable Logic Controller (Fatek) | Taiwan |

Frequency Converter (Inovance) | Joint venture |

Variable Frequency Motor (TWT) | Taiwan |

Host Header & Main Motor (Siemens) | Germany |

Encoder (RJS) | Joint-venture |

Contactor (Schneider) | France |

Photoelectric Switch (Turck) | USA |

Bearings of Key Component (NSK) | Japan |

Touch Screen (Panelmaster) | Taiwan |

Button (ABB) | Switzerland |

Module Heating Controller (Caoren) | Joint venture |

Temperature-Controlled Meter (TESHOW and CAOREN) | Joint venture |

(WEI CHI) | Joint venture |

Gluing Parts, Slitting Parts' Motor (CPG) | Taiwan |

Approach Switch (Leuze) | Germany |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Laminator Machine

Laminating Machine

Film Laminating Machine

Dry Laminating Machine

Laminating Film Machine

Cold Laminating Machine

More>>

.jpg)